Start Rolling Bottling, Labeling Tasting

November 8, 2009

After a little over a week of the wort slowly and quietly fizzing in the carboy, a 5 gallon bottle with vapor lock on top, it seemed to me that the budding brew smelled a little sweet so I thought I'd hop it up with an ounce of Cascade hops. This is called "dry hopping", where hops are introduced late in the fermentation process to provide a little extra zing. I bought some hop plugs - kind of like pesto, but derived from hops - from The Beverage People (TBP), two ounces worth. Since the yeast action was supposed to stop soon, I thought I'd better get the hops into play before the fizzing action petered out. It seemed like the thing to do was to boil some water to kill any microbes that could cause trouble and dump in an ounce of the hop plugs.

Well, the hop plugs hit the hot water and expanded into a foamy green froth that threatened to overflow the mixing container. Disaster averted, the volume was large enough to fill the carboy a little bit more than I anticipated but not to overflowing. The yeasty-beasties seemed to like the new fodder and became more energetic, belching out CO2 and fizzing more friskily. The odor of the brew took on a distinctly floral/herbal accent, and now I wondered if I had ruined the batch. Watch and wait - we'll see.

However, the fizzing continued for another week. It had been over two weeks since the wort had been put into secondary fermentation and I was beginning to be concerned. Stephen at work said that sometimes you just have to pull the plug on the brew and bottle it.

Last Wednesday was the day. First the brew had to be siphoned out of the carboy into a five gallon bucket to leave behind the layers of yeast that had built up during the secondary fermentation. That done, I added priming sugar to a pan of boiling water, let it cool, and added it to the brew in the bucket. This would give the yeast a little kick to perform was is called "bottle conditioning": the yeast comes back to life a little bit, generates CO2, and naturally carbonate the brew. Next the bucket went up onto the kitchen counter - the bottling phase was under way.

I pulled out the champagne bottles that Vince had collected for me from the Saddle Club. I had sterilized these a few weeks ago; they were waiting upside down in their cases. Bottling is a siphoning operation at this brewery, and since the bucket was up on the counter the bottles had to be below it. To avoid spilling problems from hitting the floor, I drafted a broiler pan into the operation (a drip pan, essentially, with a slotted plate on top of it) and found it to be just the right size to hold nine champagne bottles.

I'd bought a bottle filler from TBP that consisted of a foot-long piece of clear plastic tubing with a valve on one end that had a little peg sticking out; push down on the valve end, the peg pushes back on the valve, brew flows out, lift up on the tube, the flowing brew is cut off. This way you can place the filler into the bottle and no brew flows until you press against the bottom of the bottle. You leave it there until the bottle fills up completely, then lift up. The flow stops, the filler is drawn out of the bottle and then inserted into the next empty bottle for filling. The filler takes up just enough volume that when it is withdrawn from the bottle a small air gap is introduced into the neck of the bottle - just as it is in commercially bottled beer.

The valve didn't always close as designed so the broiler pan came in handy in a couple of overflow incidents. Once nine bottles were filled I'd cap them with a capping tool from TBP that had two modes - capping standard beer bottles and capping champagne bottles. It's a funny-looking thing: red plastic with two handles. Once capped the bottles were rinsed and dried; it was time to label them.

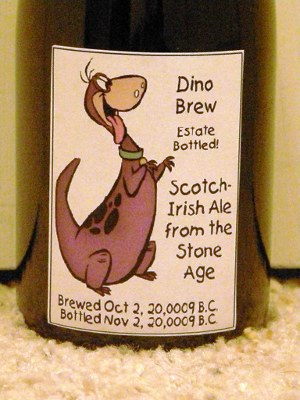

Labeling is a seductive process. There are probably some people out there dreaming up fantastic names and graphics for batches of beer they'll never brew. I've heard of all kinds of names for beer concocted for specific experiences in people's lives - one is Road Rash Ale, brewed by a Georgia woman who had taken an unpleasant spill on her bicycle - but the name for this Sonoma County batch is based on place, not event. Since we live on Dino Court we get nudges from fans of the Flintstones cartoon show about the pet dinosaur Fred and Wilma kept called Dino. It wasn't too hard to find an image of Dino on the 'Net, so I pulled it into a free graphics program called Inkscape, added some text fields around it done in a font called 'First Grade' (for a Stone Age look), sized the graphic and text to fit a beer label, imported into MS Word, copy-pasted the image to put six on a page, and hey presto!

Labeling is a seductive process. There are probably some people out there dreaming up fantastic names and graphics for batches of beer they'll never brew. I've heard of all kinds of names for beer concocted for specific experiences in people's lives - one is Road Rash Ale, brewed by a Georgia woman who had taken an unpleasant spill on her bicycle - but the name for this Sonoma County batch is based on place, not event. Since we live on Dino Court we get nudges from fans of the Flintstones cartoon show about the pet dinosaur Fred and Wilma kept called Dino. It wasn't too hard to find an image of Dino on the 'Net, so I pulled it into a free graphics program called Inkscape, added some text fields around it done in a font called 'First Grade' (for a Stone Age look), sized the graphic and text to fit a beer label, imported into MS Word, copy-pasted the image to put six on a page, and hey presto!

There was a little more to it, though. Getting the labels to stick to the bottle turned to be more involved than it needed to be. I'd bought some pre-gummed label paper from TBP (moisten and stick) that said it was good to go for laser printing as well as inkjet. I favored the color laser approach because concern that any water/brew on an inject-produced label would cause the ink to run. However, the massive color laser printer at the local office supply shop jammed on the paper after spitting out a couple of pages; maybe the thing to do was get copies made on standard paper and put some adhesive on the back. Any label stuck on had to be easy to soak off, since the bottles will be reused and relabeled - no Avery labels for you, nano-brewer! Something sticky that could be thinned out and brushed on that was water-soluble. I put out an APB to my Arts and Crafts contacts for suggestions.

I learned a lot about hide glue and Aleene's Tacky glue, but in the end I tried inkjet printing at home with TBP paper, held my breath as I applied the labels to the second case of bottles, and . . . no ink smudged or ran. The color isn't as vibrant as that of the laser-color labels that made it through the commercial copier before the paper jam, but it isn't too off the mark.

Now the brew sits in its cases and bottle-conditions. I've distributed bottles to Vince, Mom, and a couple of neighbors on Dino Court. Eric, in #1, is a garage wine-maker; he gave me a bottle of his own Emma '07 Cabernet in trade. I've let everybody know that the brew is conditioning and shouldn't be popped for at least a week, and longer might be better.

Will it turn out to be a turkey or elixir? A recipe with the wrong yeast, seat-of-the-pants dry hopping, first batch brewed in decades . . . stay tuned.