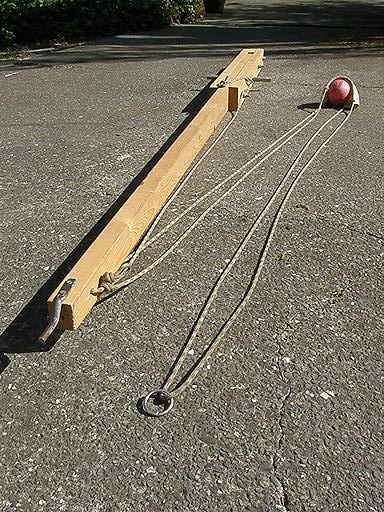

Trigger Assembly

After the trebuchet throwing arm is pulled down as far is it can go in

preparation for a launch, the

cord in the picture with the ring on the end of it is passed over the top

of the arm, then down between the two eye-bolts; a pin attached to the red

and white trigger rope is passed though one eye-bolt, the ring, and then the

other eye-bolt. The throwing arm is slowly allowed to rise until the cord

has tension on it; after that all that needs to be done is pull the red/white

trigger rope to pull the pin and the launch is under way.

The launch trough is directly under the throwing arm; without a design like

this, which has anchor points on either side of the launch trough, you would

be forced to have the trigger mechanism to one side. That would pull

the throwing arm to one side (not much, but enough) and adversely affect

the smoothness of the throw; the arm would actually be vibrating sideways

slightly during the launch.

Throwing Arm Assembly

The throwing arm has a prong on the end to hook the sling ring. It is from

a back yard gate locking hardware set - the bar that slips into the latch.

The original prong had a small ball welded to the end of it, I sawed it off

and filed down the end of the prong.

The throwing arm has a prong on the end to hook the sling ring. It is from

a back yard gate locking hardware set - the bar that slips into the latch.

The original prong had a small ball welded to the end of it, I sawed it off

and filed down the end of the prong.

The sling is made from a sliding pouch and one long, continuous piece of

cord. The reason for this is that any time any parameter is changed (weight

of object thrown, the weight of the counterweight, relocating the pivot point

in the throwing arm) the length of the sling must be adjusted to ensure an

optimal launch angle. Without an adjustable system, you'd need to have a lot

of pieces of rope of different lengths to change the sling length.

With the system shown here, a combination of a double-overhand slip knot

(which is at one end of the rope) and an overhand loop that can be tied

at any point, provides the ability to lengthen or shorten the total sling

length as needed. The excess cord is run through a hole near the end of the

throwing arm, then down to a boat cleat screwed

into the throwing arm and wrapped between the cleat and the axle.

Sliding Sling Pouch

The sling pouch can slide along the sling; there are two channels of cloth

that are folded over the cord and sewn. When the sling length is changed,

the pouch can be moved along the cord until all four sections of cord supporting

the pouch are the same length.

The sling pouch can slide along the sling; there are two channels of cloth

that are folded over the cord and sewn. When the sling length is changed,

the pouch can be moved along the cord until all four sections of cord supporting

the pouch are the same length.

Double Overhand Overhand Loop Detail

The overhand loop acts as a brake on the cord running through the double overhand

knot; the loop determines how much cord is in the sling.

The overhand loop acts as a brake on the cord running through the double overhand

knot; the loop determines how much cord is in the sling.

Storing Excess Cord

As cord is taken out of the system, depending how much is needed to get

the optimal sling lenght, it can be taken up here by wrapping it between

the axle and the cleat.

As cord is taken out of the system, depending how much is needed to get

the optimal sling lenght, it can be taken up here by wrapping it between

the axle and the cleat.

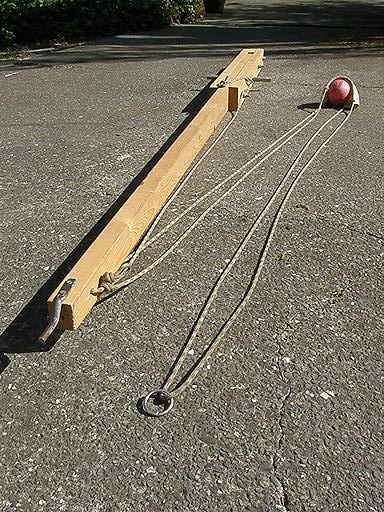

Launch Trough

The launch trough is a surprisingly important part of the system. It

ensures that the thrown object a) is kept on a straight path in the early

stage of the launch and b) accelerates

up until lift-off from a smooth surface. If this piece is neglected the thrown

object will bump along (probably hitting the carriage frame) and will not

make much of a flight.

The launch trough is a surprisingly important part of the system. It

ensures that the thrown object a) is kept on a straight path in the early

stage of the launch and b) accelerates

up until lift-off from a smooth surface. If this piece is neglected the thrown

object will bump along (probably hitting the carriage frame) and will not

make much of a flight.

The sides are made of linoleum scrap and held in place with tacks.

The throwing arm has a prong on the end to hook the sling ring. It is from

a back yard gate locking hardware set - the bar that slips into the latch.

The original prong had a small ball welded to the end of it, I sawed it off

and filed down the end of the prong.

The throwing arm has a prong on the end to hook the sling ring. It is from

a back yard gate locking hardware set - the bar that slips into the latch.

The original prong had a small ball welded to the end of it, I sawed it off

and filed down the end of the prong.

The axle rotates on bearings inserted into the carriage, on both sides.

The bearings are inset into the carriage, and are held in place by collars

mounted on the axle.

The axle rotates on bearings inserted into the carriage, on both sides.

The bearings are inset into the carriage, and are held in place by collars

mounted on the axle.

The sling pouch can slide along the sling; there are two channels of cloth

that are folded over the cord and sewn. When the sling length is changed,

the pouch can be moved along the cord until all four sections of cord supporting

the pouch are the same length.

The sling pouch can slide along the sling; there are two channels of cloth

that are folded over the cord and sewn. When the sling length is changed,

the pouch can be moved along the cord until all four sections of cord supporting

the pouch are the same length.

The overhand loop acts as a brake on the cord running through the double overhand

knot; the loop determines how much cord is in the sling.

The overhand loop acts as a brake on the cord running through the double overhand

knot; the loop determines how much cord is in the sling.

As cord is taken out of the system, depending how much is needed to get

the optimal sling lenght, it can be taken up here by wrapping it between

the axle and the cleat.

As cord is taken out of the system, depending how much is needed to get

the optimal sling lenght, it can be taken up here by wrapping it between

the axle and the cleat.

The launch trough is a surprisingly important part of the system. It

ensures that the thrown object a) is kept on a straight path in the early

stage of the launch and b) accelerates

up until lift-off from a smooth surface. If this piece is neglected the thrown

object will bump along (probably hitting the carriage frame) and will not

make much of a flight.

The launch trough is a surprisingly important part of the system. It

ensures that the thrown object a) is kept on a straight path in the early

stage of the launch and b) accelerates

up until lift-off from a smooth surface. If this piece is neglected the thrown

object will bump along (probably hitting the carriage frame) and will not

make much of a flight.